ʻO ke code no ka paʻakikī metala ʻo H. Wahi a nā ʻano hoʻāʻo paʻakikī like ʻole, ʻo nā hōʻike maʻamau e komo pū me Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS) hardness, a pēlā aku, kahi i hoʻohana pinepine ʻia ai ʻo HB a me HRC. Loaʻa iā HB kahi ākea o nā noi, a kūpono ʻo HRC no nā mea me ka paʻakikī o ka ʻili kiʻekiʻe, e like me ka paʻakikī o ka mālama wela. ʻO ka ʻokoʻa, ʻokoʻa ka indenter o ka mea hoʻāʻo paʻakikī. ʻO ka mea hoʻāʻo paʻakikī Brinell he indenter pōpō, ʻoiai ʻo ka mea hoʻāʻo paʻakikī Rockwell he indenter daimana.

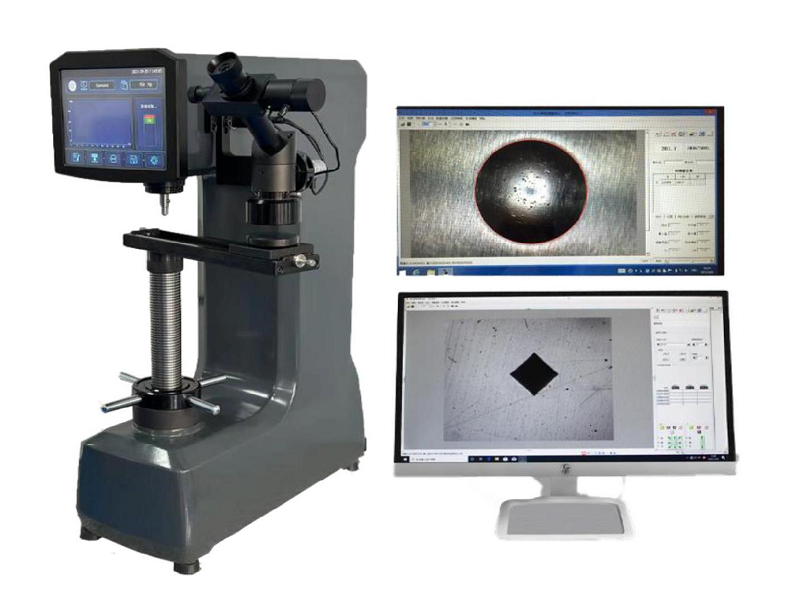

HV-kūpono no ka nānā ʻana i ka microscope. Paʻakikī Vickers (HV) E kaomi i ka ʻili o ka mea me kahi ukana ma lalo o 120kg a me kahi indenter cone huinaha daimana me kahi kihi vertex o 136°. Ua puʻunaue ʻia ka ʻili o ka lua indentation mea e ka waiwai ukana, ʻo ia ka waiwai paʻakikī Vickers (HV). Hōʻike ʻia ka paʻakikī Vickers ma ke ʻano he HV (e nānā iā GB/T4340-1999), a ana ia i nā laʻana lahilahi loa.

He kūpono ka mea hoʻāʻo paʻakikī lawe lima HL no ke ana ʻana. Hoʻohana ia i ke poʻo pōpō hopena e hoʻopilikia i ka ʻili paʻakikī a hana i kahi lele. Hoʻomaulia ʻia ka paʻakikī e ka lakio o ka wikiwiki rebound o ka punch ma 1mm mai ka ʻili laʻana i ka wikiwiki o ka hopena. ʻO ke ʻano hana: Leeb hardness HL=1000 × VB (wikiwiki rebound) / VA (wikiwiki hopena).

Hiki ke hoʻololi ʻia ka mea hoʻāʻo paʻakikī Leeb lawe lima i ka paʻakikī Brinell (HB), Rockwell (HRC), Vickers (HV), Shore (HS) ma hope o ke ana ʻana o Leeb (HL). A i ʻole e hoʻohana i ke kumumanaʻo Leeb e ana pololei i ka waiwai paʻakikī me Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS).

HB - paʻakikī Brinell:

Hoʻohana pinepine ʻia ka paʻakikī Brinell (HB) i ka wā palupalu o ka mea, e like me nā metala non-ferrous, ke kila ma mua o ka mālama wela a ma hope o ka annealing. Hoʻohana pinepine ʻia ka paʻakikī Rockwell (HRC) no nā mea me ka paʻakikī kiʻekiʻe, e like me ka paʻakikī ma hope o ka mālama wela, a pēlā aku.

ʻO ka paʻakikī Brinell (HB) kahi ukana hoʻāʻo o kahi nui. Hoʻopaʻa ʻia kahi pōpō kila paʻakikī a i ʻole ka pōpō carbide o kahi anawaena i loko o ka ʻili metala e hoʻāʻo ʻia. Mālama ʻia ka ukana hoʻāʻo no kekahi manawa i kuhikuhi ʻia, a laila wehe ʻia ka ukana e ana i ke anawaena o ka indentation ma ka ʻili e hoʻāʻo ʻia. ʻO ka waiwai paʻakikī Brinell ka quotient i loaʻa ma ka puʻunaue ʻana i ka ukana ma ka ʻāpana ʻili poepoe o ka indentation. Ma ke ʻano laulā, hoʻopaʻa ʻia kahi pōpō kila paʻakikī o kahi nui (maʻamau he 10mm ke anawaena) i loko o ka ʻili mea me kahi ukana (maʻamau he 3000kg) a mālama ʻia no kekahi manawa. Ma hope o ka wehe ʻana o ka ukana, ʻo ka lakio o ka ukana i ka wahi indentation ʻo ia ka waiwai paʻakikī Brinell (HB), a ʻo ke anakahi he kilokani ikaika/mm2 (N/mm2).

Hoʻoholo ka paʻakikī ʻo Rockwell i ka helu kuhikuhi waiwai paʻakikī e pili ana i ka hohonu o ka deformation plastic o ka indentation. Hoʻohana ʻia ʻo 0.002 mm ma ke ʻano he anakahi paʻakikī. Ke HB>450 a i ʻole ka liʻiliʻi o ka hāpana, ʻaʻole hiki ke hoʻohana ʻia ka hoʻāʻo paʻakikī Brinell a hoʻohana ʻia ke ana ʻana o ka paʻakikī ʻo Rockwell. Hoʻohana ia i kahi cone daimana me kahi kihi vertex o 120° a i ʻole kahi pōpō kila me ke anawaena o 1.59 a i ʻole 3.18mm e kaomi i loko o ka ʻili o ka mea ma lalo o ka hoʻāʻo ʻana ma lalo o kekahi ukana, a ua helu ʻia ka paʻakikī o ka mea mai ka hohonu o ka indentation. Wahi a ka paʻakikī o ka mea hoʻāʻo, ua hōʻike ʻia ma ʻekolu mau unahi like ʻole:

HRA: ʻO ia ka paʻakikī i loaʻa ma ka hoʻohana ʻana i kahi ukana 60kg a me kahi indenter cone daimana, i hoʻohana ʻia no nā mea me ka paʻakikī kiʻekiʻe loa (e like me ka carbide cemented, a pēlā aku).

HRB: ʻO ia ka paʻakikī i loaʻa ma ka hoʻohana ʻana i kahi ukana 100kg a me kahi pōpō kila paʻakikī me ke anawaena o 1.58mm, i hoʻohana ʻia no nā mea me ka paʻakikī haʻahaʻa (e like me ke kila annealed, hao i hoʻolei ʻia, a pēlā aku).

HRC: ʻO ia ka paʻakikī i loaʻa ma ka hoʻohana ʻana i kahi ukana 150kg a me kahi indenter cone daimana, i hoʻohana ʻia no nā mea me ka paʻakikī kiʻekiʻe loa (e like me ke kila paʻakikī, a pēlā aku).

Kahi mea hou aʻe:

1. ʻO HRC ke ʻano o ka pālākiō paʻakikī Rockwell C.

2. Hoʻohana nui ʻia ʻo HRC a me HB i ka hana ʻana.

3.HRC pae kūpono HRC 20-67, like me HB225-650,

Inā ʻoi aku ke kiʻekiʻe o ka paʻakikī ma mua o kēia pae, e hoʻohana i ka pālākiō Rockwell hardness A HRA,

Inā haʻahaʻa ka paʻakikī ma mua o kēia pae, e hoʻohana i ka pālākiō paʻakikī Rockwell B HRB,

ʻO ka palena kiʻekiʻe o ka paʻakikī Brinell ʻo HB650, ʻaʻole hiki ke kiʻekiʻe aʻe ma mua o kēia waiwai.

4. ʻO ka indenter o ka mea hoʻāʻo paʻakikī Rockwell C unahi he cone daimana me kahi kihi vertex o 120 degere. He waiwai kikoʻī ka ukana hoʻāʻo. ʻO ke kūlana Kina he 150 kgf. ʻO ka indenter o ka mea hoʻāʻo paʻakikī Brinell he pōpō kila paʻakikī (HBS) a i ʻole he pōpō carbide (HBW). ʻOkoʻa ka ukana hoʻāʻo me ke anawaena o ka pōpō, mai 3000 a 31.25 kgf.

5. He liʻiliʻi loa ka indentation paʻakikī Rockwell, a ua kūloko ka waiwai i ana ʻia. Pono e ana i kekahi mau kiko e loaʻa ai ka waiwai awelika. He kūpono ia no nā huahana i hoʻopau ʻia a me nā ʻāpana lahilahi a ua hoʻokaʻawale ʻia ʻo ia he hoʻāʻo luku ʻole. ʻOi aku ka nui o ka indentation paʻakikī Brinell, pololei ka waiwai i ana ʻia, ʻaʻole kūpono ia no nā huahana i hoʻopau ʻia a me nā ʻāpana lahilahi, a ʻaʻole i hoʻokaʻawale ʻia ʻo ia he hoʻāʻo luku ʻole.

6. ʻO ka waiwai paʻakikī o ka paʻakikī Rockwell he helu inoa ʻole me ka ʻole o nā anakahi. (No laila, he hewa ke kapa ʻana i ka paʻakikī Rockwell ma ke ʻano he kekelē.) Loaʻa i ka waiwai paʻakikī o ka paʻakikī Brinell nā anakahi a he pilina kokoke me ka ikaika tensile.

7. Hōʻike pololei ʻia ka paʻakikī o Rockwell ma ke pihi a i ʻole hōʻike ʻia ma ke ʻano kikohoʻe. He maʻalahi ke hana, wikiwiki a maʻalahi hoʻi, a kūpono no ka hana nui ʻana. Pono ka paʻakikī o Brinell i kahi microscope e ana i ke anawaena indentation, a laila e nānā i ka papa a i ʻole e helu, ʻoi aku ka paʻakikī o ka hana.

8. Ma lalo o kekahi mau kūlana, hiki ke hoʻololi ʻia ʻo HB a me HRC ma ka nānā ʻana i luna o ka papa. Hiki ke hoʻopaʻa ʻia ke ʻano helu noʻonoʻo penei: 1HRC≈1/10HB.

He ʻano hoʻāʻo maʻalahi a maʻalahi hoʻi ka hoʻāʻo paʻakikī i ka hoʻāʻo waiwai mechanical. I mea e hoʻohana ai i ka hoʻāʻo paʻakikī e pani i kekahi mau hoʻāʻo waiwai mechanical, pono kahi pilina hoʻololi pololei ma waena o ka paʻakikī a me ka ikaika i ka hana ʻana.

Ua hōʻoia ka hana maʻamau aia kahi pilina pili like ma waena o nā waiwai paʻakikī like ʻole o nā mea metala a ma waena o ka waiwai paʻakikī a me ka waiwai ikaika. No ka mea ua hoʻoholo ʻia ka waiwai paʻakikī e ke kū'ē mua o ka deformation plastic a me ke kū'ē mau o ka deformation plastic, ʻoi aku ka kiʻekiʻe o ka ikaika o ka mea, ʻoi aku ka kiʻekiʻe o ke kū'ē ʻana o ka deformation plastic, a ʻoi aku ka kiʻekiʻe o ka waiwai paʻakikī.

Ka manawa hoʻouna: Aug-16-2024